Understanding Life Cycle Costing in Engineering Projects

Introduction to Life Cycle Costing

Welcome to the world of engineering projects, where innovation meets practicality and creativity is coupled with precision. As engineers, we are constantly striving to find the most efficient solutions that not only deliver exceptional performance but also prove cost-effective in the long run. This is where Life Cycle Costing comes into play - a powerful tool that allows us to analyze and evaluate the financial implications of our decisions throughout the entire lifespan of a project.

In this blog post, we will dive deep into understanding Life Cycle Costing and explore its significance in engineering projects. We will uncover its key components, advantages, disadvantages, as well as discuss some common challenges faced during implementation. So buckle up your seatbelts because we are about to embark on an exciting journey through the fascinating realm of Life Cycle Costing!

Why is Life Cycle Costing Important in Engineering Projects?

Life Cycle Costing is a critical aspect of engineering projects that should not be overlooked. It provides a comprehensive analysis of the costs associated with a project throughout its entire life cycle, from conception to disposal. This approach considers not only the initial investment but also ongoing operational and maintenance costs, as well as potential future expenses.

One key reason why Life Cycle Costing is important in engineering projects is that it allows for better decision-making. By considering all costs involved over the project's lifetime, engineers can make more informed choices about materials, equipment, and design options. This helps minimize long-term expenditures while maximizing efficiency and sustainability.

Additionally, Life Cycle Costing enables accurate cost forecasting. By accounting for potential maintenance and replacement expenses down the line, engineers can develop realistic budgets and financial plans. This prevents any unexpected financial burden during the project's operation phase.

Furthermore, Life Cycle Costing promotes accountability. By understanding the full cost implications of their decisions upfront, engineers are motivated to prioritize quality and longevity in their designs rather than opting for cheaper short-term solutions.

This approach aligns with sustainable development goals by encouraging environmentally friendly practices. Engineers can assess how different design choices impact energy consumption or waste generation over time and make adjustments accordingly.

Life Cycle Costing plays a vital role in engineering projects by providing a holistic view of costs incurred throughout an asset's life cycle. Through better decision-making capabilities and improved cost forecasting accuracy, engineers can optimize resource utilization while ensuring long-term viability.

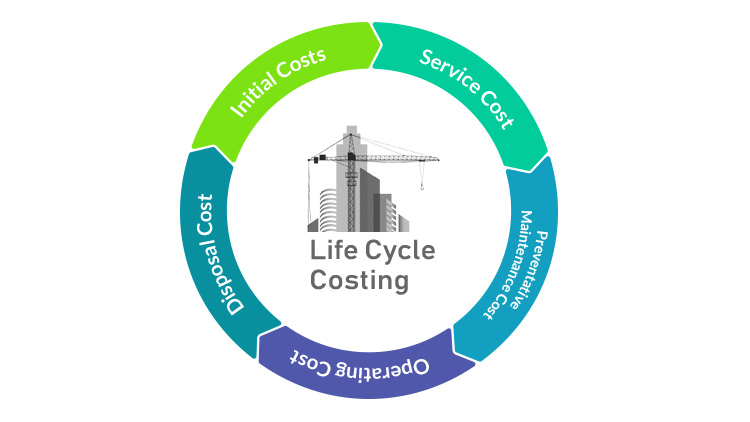

The Components of Life Cycle Costing

When it comes to understanding the true cost of an engineering project, life cycle costing plays a crucial role. It involves considering all the costs associated with a project from its inception to its disposal. Let's take a closer look at the components that make up this comprehensive approach.

There are the initial costs, which include everything from research and development expenses to procurement and installation costs. These upfront expenditures set the foundation for the entire project and need careful consideration.

Next, we have operating costs. These encompass ongoing expenses such as maintenance, repairs, energy consumption, and labor costs throughout the lifespan of the project. By factoring in these operational expenses early on, engineers can better estimate long-term financial implications.

Another important component is replacement or upgrade costs. Over time, technology advances rapidly; therefore, equipment may become obsolete or require upgrades to remain efficient and compliant with regulations. Including these future expenses in life cycle costing helps avoid unexpected financial burdens down the line.

Furthermore, we must consider downtime costs caused by interruptions in production or service delivery due to equipment failure or maintenance work. These disruptions can result in lost productivity and potential revenue loss if not accounted for during planning stages.

Lastly but equally significant are disposal or decommissioning costs when a project reaches its end-of-life stage. This includes environmental cleanup measures as well as safe removal and disposal of any hazardous materials used during construction or operation.

By taking into account all these components – initial costs, operating expenses,

replacement/upgrades fees , downtime losses ,and disposal/decommissioning expenditures – engineers gain a holistic view of a project's total cost over its entire lifecycle.

Advantages and Disadvantages of Life Cycle Costing

When it comes to engineering projects, considering the life cycle costing can offer several benefits. First and foremost, this approach ensures that all costs associated with a project are taken into account from its inception to its retirement. By accounting for costs throughout the entire life cycle, decisions can be made based on a comprehensive understanding of long-term implications.

One major advantage of life cycle costing is that it helps identify cost-saving opportunities. By analyzing different alternatives over the entire life span of a project, engineers can pinpoint areas where savings can be achieved. This proactive approach allows for informed decision-making early on in the project's development, leading to more efficient use of resources.

Furthermore, life cycle costing encourages sustainability considerations. It prompts engineers to evaluate not only financial costs but also environmental impacts associated with each stage of a project's lifecycle. This holistic perspective fosters environmentally conscious decision-making and promotes sustainable practices.

However, there are some potential disadvantages to consider as well when implementing life cycle costing in engineering projects. One challenge is accurately forecasting future costs due to uncertainties such as inflation rates or changes in technology. Predicting these factors with certainty can be difficult and may introduce inaccuracies into cost estimates.

Another drawback is that conducting an extensive analysis spanning multiple years requires time and resources which may not always be readily available during tight deadlines or budget constraints. The comprehensive nature of life cycle costing demands meticulous data collection and analysis which could potentially delay decision-making processes if not managed efficiently.

While there are advantages to employing life cycle costing in engineering projects such as identifying cost-saving opportunities and promoting sustainability consideration; challenges like accurate cost forecasting and resource requirements need careful consideration before implementation.

Challenges and Solutions for Implementing Life Cycle Costing in Engineering Projects

Implementing life cycle costing in engineering projects can present certain challenges, but there are also solutions available to overcome them. One challenge is the complexity of gathering accurate data throughout the entire project lifecycle. This can involve collecting information from various sources and ensuring its reliability. To address this challenge, implementing standardized data collection methods and utilizing advanced technology such as automated data capture systems can greatly improve accuracy and efficiency.

Another challenge is the uncertainty surrounding future costs and variables that may impact the project over time. Factors like inflation rates, market fluctuations, and changing regulations can all affect cost projections. One solution to mitigate this challenge is conducting thorough research and analysis to identify potential risks and develop contingency plans accordingly. Regular monitoring of relevant external factors during the project's lifespan will also help adjust cost estimates as needed.

Additionally, resistance or lack of awareness among stakeholders about life cycle costing principles can hinder successful implementation. Education and communication play a crucial role here by raising awareness about the benefits of life cycle costing and demonstrating how it aligns with long-term goals such as sustainability or profitability.

Furthermore, integrating life cycle costing into existing project management processes might require changes in workflows or additional training for team members involved. By providing clear guidelines on how to incorporate life cycle costing practices into daily operations, organizations can facilitate smooth adoption without disrupting ongoing projects.

Obtaining sufficient financial resources upfront for comprehensive analysis throughout a project's duration may be seen as challenging by some organizations due to budget constraints or competing priorities. However, highlighting the potential return on investment through improved decision-making based on accurate cost assessments could help secure necessary funding.

While implementing life cycle costing in engineering projects presents challenges related to data collection complexity, uncertainty regarding future costs,

stakeholder resistance or lack of awareness

integration into existing processes

and securing adequate resources,

there are solutions available including standardizing data collection methods

utilizing advanced technology

conducting thorough research and analysis

raising awareness through education and communication.

Conclusion

Life cycle costing is a crucial tool in engineering projects that helps businesses make informed decisions about their investments. By considering not only the initial costs but also the costs throughout the entire life cycle of a project, companies can better understand the financial implications and potential risks associated with their decisions.

Throughout this article, we have explored the importance of life cycle costing in engineering projects. We have discussed its components, advantages, disadvantages, as well as challenges and solutions for implementing it effectively.

By adopting life cycle costing practices, businesses can accurately assess the total cost of ownership of assets or projects. This allows them to optimize resources allocation, minimize expenses over time, and ensure long-term profitability.

However, implementing life cycle costing comes with its fair share of challenges. It requires accurate data collection and analysis at each stage of a project's life span. Additionally, there may be resistance from stakeholders who are more focused on short-term gains rather than long-term benefits.

To overcome these challenges, organizations should invest in robust data management systems and establish clear communication channels between all parties involved in decision-making processes. Training programs can also help educate employees about the importance of considering all relevant costs throughout a project's lifetime.

In conclusion (Oops! I meant to say "to wrap things up"), understanding life cycle costing is essential for successful engineering projects. By taking into account all costs associated with an asset or project from conception to disposal or decommissioning stages while considering uncertainties such as maintenance needs and market changes – businesses can make informed choices that align with their strategic objectives.

So next time you embark on an engineering project or consider investing in new equipment or infrastructure - remember to think beyond just upfront expenditures! Life cycle costing will guide you towards making financially sound decisions that promote sustainability and maximize returns on investment.

Comments

Post a Comment